Galvanic Corrosion is corrosion damage created when dissimilar materials are joined by a corrosive electrolyte. Galvanic Corrosion is a common type of corrosion found in Marine Environments. For example, two dissimilar metals such as Stainless Steel and Aluminium touching and an electrolyte such as salt-water or even rain water (made worse if there is a high salt content in the atmosphere I.e. coastal). This is a problem on Yachts masts where Stainless Steel fasteners are in contact with Aluminium or Carbon Fibre masts, or on roofing where lead or copper flashings are in contact with a Zincalume R roof.

When two different metals are in contact with a corrosive solution, each will develop a corrosion potential and become positive/negative ends of an electric circuit. A measurable current may flow between the anode and the cathode. The corrosion rate of the anode will be increased and the cathode decreased. The increased corrosion of the anode is called “galvanic corrosion”. For Galvanic Corrosion 3 things are required:

1) Dissimilar metals (E.g. Stainless and Aluminium)

2) Metal-to-metal contact

3) Metals in the same conduction solution (usually called an electrolyte – E.g. salt water)

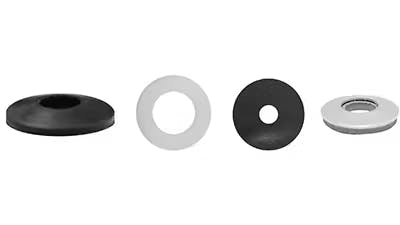

If any of these elements is missing, galvanic corrosion cannot occur. If, for example, the direct contact between the two metals is prevented (plastic washer, paint film etc.) there cannot be galvanic corrosion. This could be achieved through Nylon washers, other plastic or rubber washers or Tef-Gel which creates a barrier between dissimilar metals.

In a ‘Galvanic Couple’, one metal will be the anode and one the cathode. The corrosion rate of the anode will be increased (e.g. zinc or aluminium will corrode faster and so is sacrificial) and the cathode will decrease (e.g stainless will corrode less and is protected). The increased corrosion of the anode is called “galvanic corrosion”.

The “Galvanic Series in seawater” lists the common metals in order from the most anodic to most cathodic (noble). The further apart the metals are in this series, the greater the corrosion difference and speed between the two. For example Zinc will corrode in Salt Water extremely quickly in contact with Platinum, but 304 Stainless Steel in contact with 316 Stainless Steel will have little effect over each other .

The surface area of the Anode versus Cathode will also effect corrosion speed. For example a small stainless screw in a large aluminium yacht’s mast will pit the aluminium only slightly to moderately (reduced by using Tef-Gel) – but a small aluminium screw in a larger stainless fitting with seawater will mean the small aluminium screw corrodes extremely fast.

In summary, dissimilar metal combinations should be avoided in areas where moisture is likely to accumulate and remain for long periods. Nylon washers, other plastic or rubber washers, Tef-Gel or other means should be used to separate metals.

Sources: Galvanic Corrosion, type of corrosion found in Marine Environments, Galvanic Series in seawater

NB: This information is provided as a guide only and Anzor does not accept liability for the application of this information.

Build Your Deck Faster With Our Decking Screw Calculator

Super Duplex 2507 Stainless Steel for Engineering & Manufacturing

To receive useful info and product updates add your details below