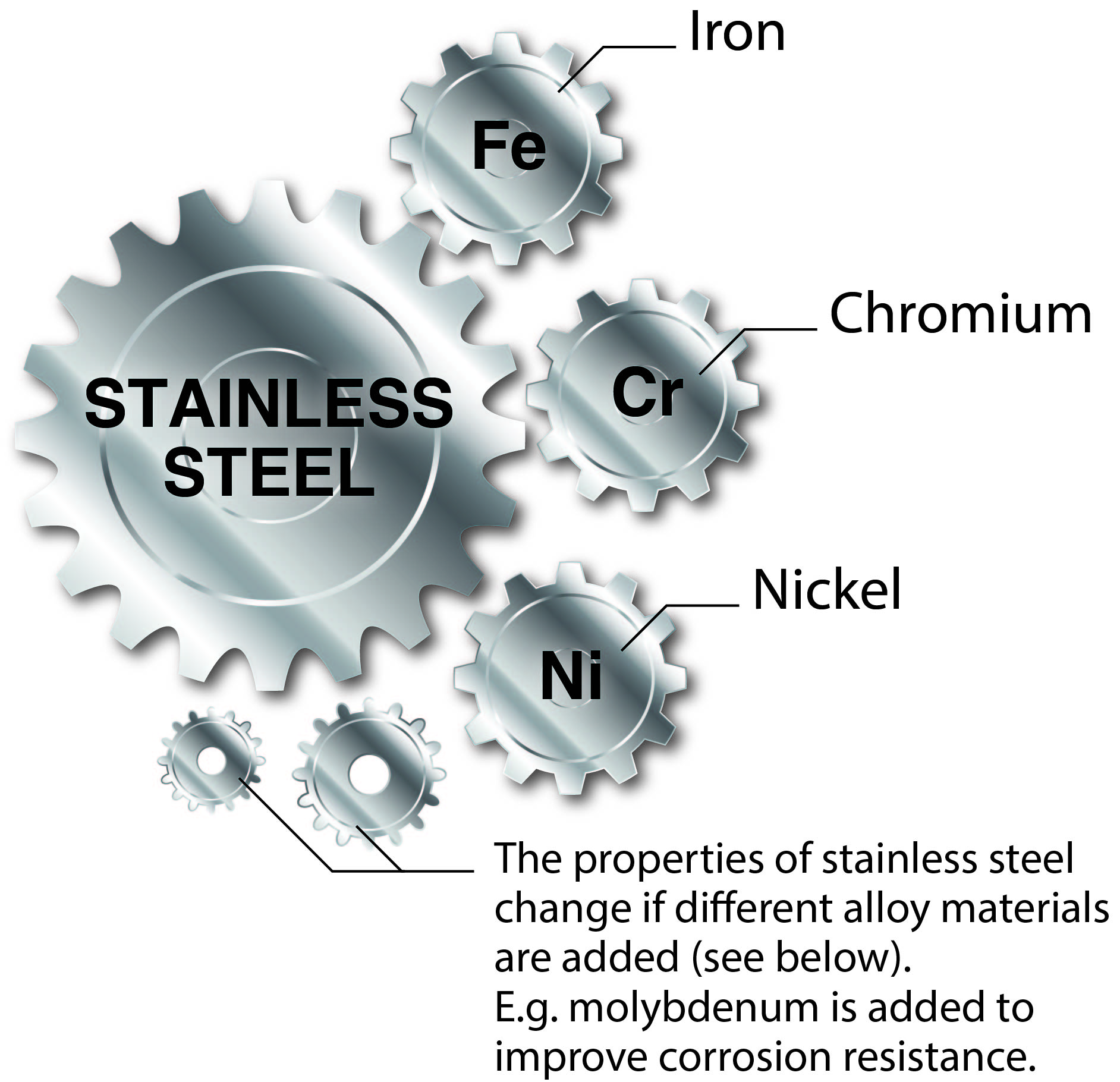

Because it has a naturally occurring protective layer on its surface that protects it from corrosion. This is due to the chromium it contains – any steel alloy that contains a minimum of 10.5% chromium is considered to be stainless steel.

|

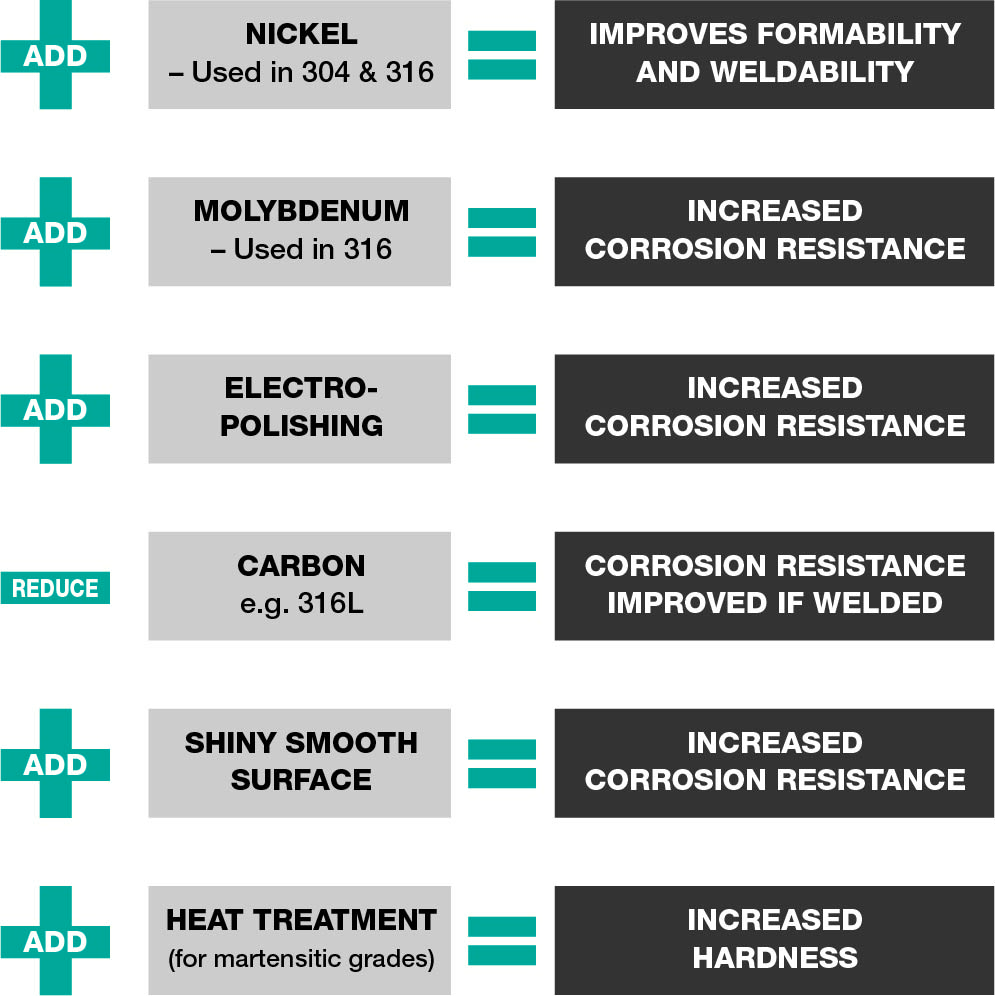

Stainless steel is a solid metal and not just a coating applied to steel. The chromium in the stainless steel combines with oxygen in the normal environment to form a ‘chromium oxide’ or a ‘passive film’ layer on the surface. This protects the iron in the steel from being attacked by corrosive agents (e.g. salt) and creating rust. When the chromium oxide layer is damaged mechanically or chemically... ...it repairs itself – assuming oxygen (even in very small amounts) is present. NB: that’s why most stainless steels (except super duplex 2507) don’t perform when submersed in salt water because there isn’t enough oxygen to generate the chromium oxide layer. |

|

Rust/Stain Resistant - If the chromium oxide layer is maintained and not under regular mechanical vibration, it should probably last forever. |

|

Maintains looks over time - Depending on a range of factors (finish, grade, environment, cleaning) stainless should maintain its appearance over time. |

|

Delivers value for money - In general, it outlasts steel coatings (e.g. zinc or galvanizing), so overall delivers a lower cost over the entire life-cycle. |

|

Relatively strong - In terms of tensile strength, it can range from 500 to 1000 MPa. |

|

Recyclable - Stainless steel is 100% recyclable and non-toxic. |

Stainless steel is also known as ‘inox steel’ or ‘inox’ from French ‘inoxydable’

NB: This is provided as a guide only. Anzor does not accept liability for the application of this informaiton. For advice about stainless steel, contact the Nickel Institute.

There are more than 60 grades of stainless steel. However, all stainless steels can be divided into one of five types identified by their main crystal structures:

|

Austenitic

|

|

Ferritic

|

|

Duplex

|

|

Martensitic

|

|

Precipitation Hardening (PH)

|

Build Your Deck Faster With Our Decking Screw Calculator

Super Duplex 2507 Stainless Steel for Engineering & Manufacturing

To receive useful info and product updates add your details below